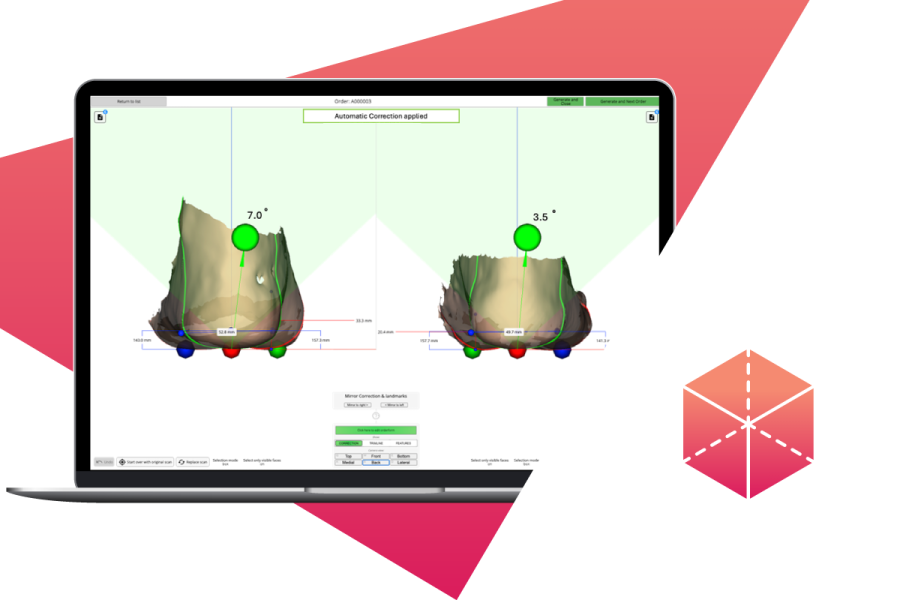

Ensuring proper alignment of the scanned foot/ankle to the calcaneus vertical is a critical aspect of the design process in foot and ankle applications. This alignment may be required due to factors such as scanning protocol when capturing the foot, the suspension technique used, or the foot anatomy and pathology.

Our innovative neural network-based approach streamlines this alignment process by analyzing the scans and automatically calculating the deviation between the rearfoot and forefoot.

The AI analysis looks at the shape of the cross-sections of the rearfoot combined with analysis of the foot shape from multiple angles. The system is trained on many thousands of foot scans processed through the system and validated or aligned by expert technicians allowing exceptional accuracy and performance.

Depending on the prescription, the calcaneus may then be automatically rotated to the correct orientation with remarkable reliability. This significantly improves consistency and accuracy and reduces manual intervention in the design process, facilitating true automation based on accurate foot orientation.

Calcaneus alignment is one of the key features of the AI-driven scan processing step within TaikaCreate.

Scan processing begins with the input of scanned data and basic 3d shape recognition. This is followed by automated scan cleaning, anatomical landmark detection, the removal of unnecessary surfaces, the rotation and correction of the foot model, the application of modification rules, and the calculation of key measures.

After scan processing, TaikaCreate automatically applies the individual prescription details to swiftly generate the device model. Each implementation of the TaikaCreate platform is unique to the orthotics lab, respecting the experience and knowledge of that technical team.

All of the resulting automatic designs are then reviewed by an expert operator to validate the design and export to the production method of choice.