Six years ago, our founders from the UK and Finland embarked on a mission to revolutionize the way custom insoles are designed. They recognized the challenge of creating complex custom designs quickly and consistently. Fueled by a desire to improve repetitive and time-consuming design processes, they teamed up to develop a cutting-edge solution, and Taika3D was born! Today, we are proud to be the world leader in design automation for custom devices, supporting leading manufacturers in creating thousands of custom orthotics every day.

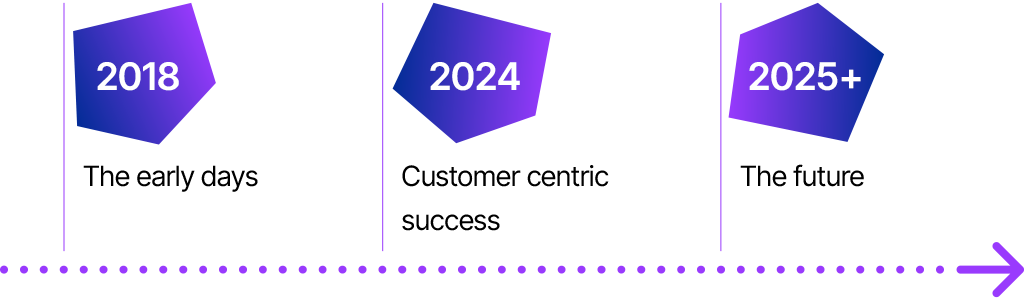

As we celebrate our 6th anniversary in the month of September, we reflect on our journey so far, our achievements, and our vision for the future.

Building the Foundations

In the early days, we focused on careful experimentation and refining our software to align with industry needs. We understood that designing custom insoles required attention to numerous factors, including anatomical precision, material choice, biomechanical considerations, technological integration, and the balance between aesthetics and functionality, all while ensuring regulatory compliance for the end product. Our goal was to create a solution that met all these criteria for our future customers. Although we faced challenges along the way, each one brought us closer to achieving our vision. The support from our funding network and the trust of our early adopters played a crucial role in shaping our path.

Breakthroughs and Milestones

Data Capture Scanning

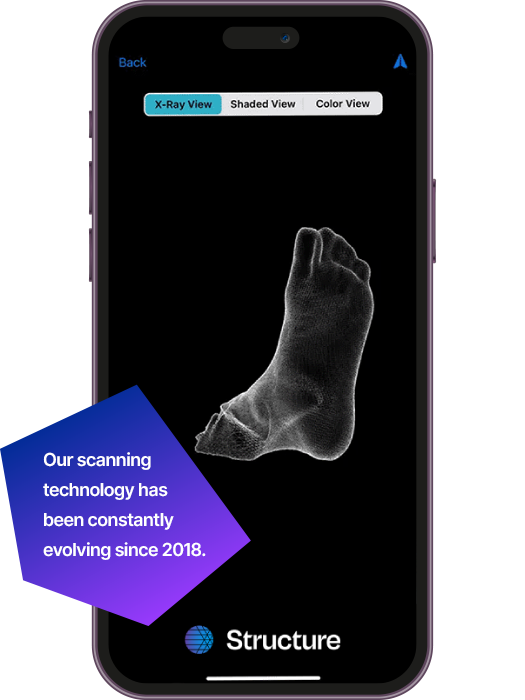

Since the beginning, our team has been dedicated to developing scanning technology — an essential component for customers needing to capture accurate patient data for insole design. Recognizing this need, we started creating scanning apps for our early partners in 2018. By 2019, we had pilot solutions ready for deployment, and these have since evolved into the seamless scanning experience our customers enjoy today.

Face ID

While our software is compatible with all scanning solutions, in 2022, we began developing Face ID for scanning, alongside the Structure Sensor scanning technology, to provide our customers with enhanced flexibility and convenience. By 2023, our pilot programs demonstrated how effectively Face ID could be used for precise and accessible scanning, specifically designed for iPhone and iPad users, marking a pivotal shift to high precision in data capture, as well as significantly enhancing the user experience and outcomes.

Web Order Form

As part of our data capture process, in 2023, we transitioned to a Web Order Form (WOF) to enhance the customer experience. The WOF allows customers to place detailed clinical insole orders using a tablet, laptop, or desktop, offering greater flexibility compared to the traditional app-based system. This web-based platform simplifies the ordering process, making it a more user-friendly, efficient and accessible way for our customers to manage their orders.

Custom Insole Design Automation

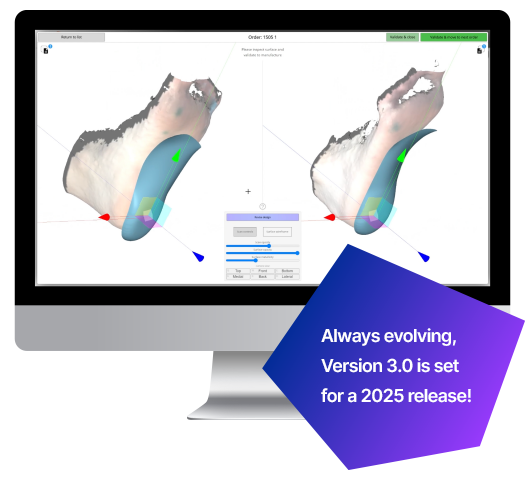

This is where the magic happens! Our design automation solution has undergone several transformative updates, each bringing significant improvements in functionality and performance. We began with Version 1.0 in 2018, which marked the launch of the TaikaCreate design platform. The following year, Version 1.5 introduced the Milling Manager, enhancing our customers’ capabilities for milling operations, followed by Version 2.0 which focused on refining user management, improving access and control for a better overall experience.

Fast forward to 2023, Version 2.5 represented a major upgrade with the integration of new AWS infrastructure, including advanced features like terraforming, helping to improve scalability and performance. Looking ahead to 2025, Version 3.0 is set to continue this evolution, promising further advancements in architecture and functionality. With each update, we’ve been relentless in improving user management and optimizing the performance of our platform and database.

Hello to the Milling Manager

Recognizing the widespread use of conventional manufacturing, we introduced the Milling Manager as a key feature in 2019, with pilots ready that same year. This integral component of our solution simplifies the setup of large milling jobs tailored to specific requirements. It efficiently generates NC codes for milled devices, manages milling templates, and oversees machine-driven outputs, delivering a customized and streamlined experience for every user.

Investor Support and Funding

We are hugely thankful to our diverse group of investors, including founders, friends and family, as well as Business Finland, whose steadfast support has been crucial to our innovation and growth. The backing from angel investor Leena Niemistö, Kaikarhenni Oy and Hippocras Ky, and family fund Thomasset Oy, Vesa Tuomi and Jussi Heinilä, along with private venture capital firms such as Nina Capital and Butterfly Ventures, right from the beginning, has played a pivotal role in driving our progress and success.

Customer-Centric Success

We are proud to now have a significant customer base in North America, with a growing presence across Europe and other global markets. Currently, we are designing over 28,000 insoles every month and meeting the diverse needs of our customers. As part of our commitment to ongoing customer support, our Senior Development team recently took an extended trip across the United States to visit customers, answer technical questions, and ensure all-round satisfaction with Taika3D software and bespoke implementations.

Accelerating Growth

At Taika3D, we are excited about the future as we grow our customer base and broaden our product portfolio with innovative new offerings later this year, addressing critical needs and providing new devices.

We are forging strategic partnerships with cutting-edge 3D printing and scanning companies, to provide unparalleled quality and service, as well as exploring new business models for the European market and participating in European Orthotic projects to strengthen and solidify our leadership in the industry. With the continued support of our investors and valued customers, we are well-positioned to help our network deliver outstanding services and products to their clients.

Steve Cook, Co-Founder and CEO says “Reflecting on our six-year journey, I am deeply proud of how Taika3D has evolved from a bold idea into a global leader in design automation. This success is a testament to the dedication of our team, the trust of our partners, and the unwavering support of our customers. Together, we’ve not just built a company—we’ve set a new standard in our industry. Here’s to the future, where our innovation will continue to empower and drive growth for our cutomers.”

Thank you for following our six-year journey. Join Us in Celebrating! Connect with us on social media, share your Taika3D experiences, and stay tuned for updates. Here’s to many more years of great collaboration with our customers, growth, and success!