Ready for your tour of the Taika3D system?

Are you looking to transform your central fab facility’s digital design throughput in foot orthotic production? With Taika3D’s revolutionary design software, you can create individual custom orthotics in less than one minute per pair. With a seamless integration of digital order forms and scan uploads, streamline the entire design process and benefit from unique designs at scale with no compromise on quality.

Input 3D scan data with individual prescription information from a combination of more than 100 features and clinical modifications and watch our design engine deliver hands-off design automation of anywhere between 60-100 pairs of custom orthotics per designer per hour. The software creates production-ready files either as a CNC file or as a 3D print, built from the customer’s rules and existing templates. With unlimited client and user licenses and no limit to installations, Taika3D offers unlimited capacity for scaling your business.

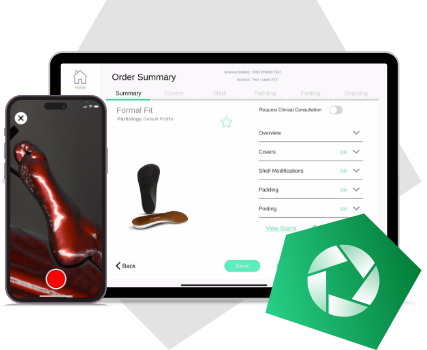

TaikaCapture

Digital capture of shape and prescription needs

A fully customized application for professional scanning, whatever your clinical approach. Fast, simple, stable.

TaikaCreate

Design generation

Automatically create 3D models rapidly and consistently with design automation of 60-100 pairs per designer per hour.

Grow with Taika3D

Scale design productivity now

Discover the benefits of using our bespoke software solution for rapid, consistent and print-ready output.

Discover how our range of software solutions can help transform your orthotics business.

Schedule a demonstration today.

Automated solutions for unique designs at scale

Improve reliability, accuracy and consistency of designs

Boost productivity – up to 60-100 pairs of custom insoles per designer per hour!

Produce complex user-specific models ready for 3D print or CNC machining

Full end-to-end digital solutions integrated into your business processes

Options for 3D scanning solutions and custom web order forms