Ready for your tour of the Taika3D system?

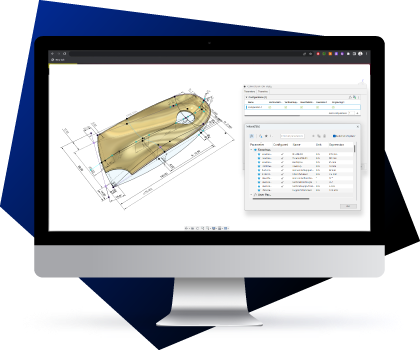

Taika3D integrates with the leading custom insole 3D printers, creating configurable end-to-end workflows enabling O&P manufacturers to maximise output.

We assist our customers in selecting the most appropriate 3DP systems based on their requirements and production volumes.

Learn more about some of our existing 3DP partnerships below, and contact the Taika3D team for a tour of our system today.

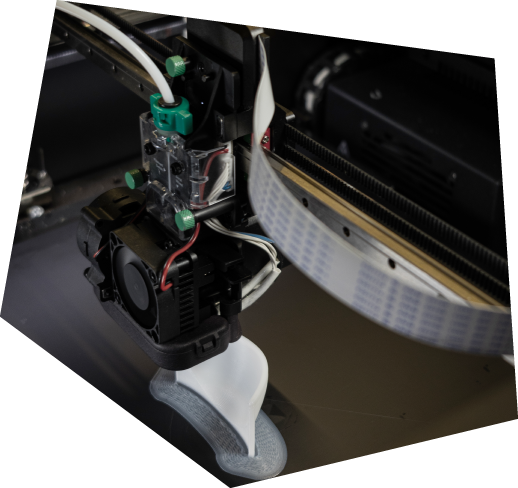

Array takes the cost, mess, and waste out of custom foot orthotic production. Array directly prints functional and accommodative foot orthotics, producing over 500 pairs a month with limited operator intervention. The patented automation technology has revolutionized 3D printing production, making it truly accessible to O&P labs for the first time.

Array is compatible with a wide selection of O&P materials; Polypropylene & polycarbonate are popular choices for functional FOs, and Mosaic Aero offers a cushion-like feel – similar to an EVA foam – making it great for accommodative FOs.

– Aligned for FFF print beds

– Self generated supports

– Nested build volumes

Scale faster production of unique and consistent O&P products with Taika3D and our 3D insole production partners. Request more information today.