Ready for your tour of the Taika3D system?

Taika3D are a Finnish-based company working with clients across the globe to provide world-class custom orthotics software.

Our company name Taika3D is based on the Finnish word Taika, meaning “Magic”! We like to think this is a reference to the fact that our design generation software is pretty miraculous!

Back in 2018, our founders from the UK and Finland embarked on a mission to revolutionize the way custom

insoles are designed. They recognized the challenge of creating complex custom designs quickly and

consistently. Fueled by a desire to improve repetitive and time-consuming design processes, they teamed up

to develop a cutting-edge solution, and Taika3D was born! Today, we are proud to be the world leader in

design automation for custom devices, supporting leading manufacturers in creating thousands of custom

orthotics every day.

Our journey so far has been one of achievement, and a strong vision for the future…

Back in 2018, our founders from the UK and Finland embarked on a mission to revolutionize the way custom insoles are designed. They recognized the challenge of creating complex custom designs quickly and consistently. Fueled by a desire to improve repetitive and time-consuming design processes, they teamed up to develop a cutting-edge solution, and Taika3D was born! Today, we are proud to be the world leader in design automation for custom devices, supporting leading manufacturers in creating thousands of custom orthotics every day.

Our journey so far has been one of achievement and a strong vision for the future.

Since the beginning, our team has been dedicated to developing scanning technology—an essential component for customers needing to capture accurate patient data for insole design. Recognizing this need, we started creating scanning apps for our early partners in 2018. By 2019, we had pilot solutions ready for deployment, and these have since evolved into the seamless scanning experience our customers enjoy today.

While our software is compatible with all scanning solutions, in 2022, we began developing Face ID for scanning, alongside the Structure Sensor scanning technology, to provide our customers with enhanced flexibility and convenience. By 2023, our pilot programs demonstrated how effectively Face ID could be used for precise and accessible scanning, specifically designed for iPhone and iPad users, marking a pivotal shift to high precision in data capture, as well as significantly enhancing the user experience and outcomes.

As part of our data capture process, in 2023, we transitioned to a Web Order Form (WOF) to enhance the customer experience. The WOF allows customers to place detailed clinical insole orders using a tablet, laptop, or desktop, offering greater flexibility compared to the traditional app-based system. This web-based platform simplifies the ordering process, making it a more user-friendly, efficient, and accessible way for our customers to manage their orders.

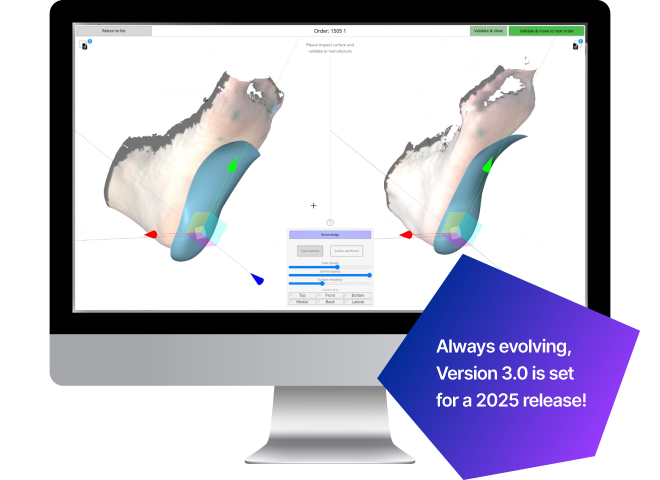

Fast forward to 2023, Version 2.5 represented a major upgrade with the integration of new AWS infrastructure, including advanced features like terraforming, helping to improve scalability and performance. Looking ahead to 2025, Version 3.0 is set to continue this evolution, promising further advancements in architecture and functionality. With each update, we’ve been relentless in improving user management and optimizing the performance of our platform and database.

Recognizing the prevalence of conventional manufacturing, we introduced the Milling Manager as a key feature in 2019, with pilots ready that same year. This integral component of our solution simplifies the setup of large milling jobs tailored to specific requirements. It efficiently generates NC codes for milled devices, manages milling templates, and oversees machine-driven outputs, delivering a customized and streamlined experience for every user.

We are hugely thankful to our diverse group of investors, including founders, friends, and family, as well as Business Finland, whose steadfast support has been crucial to our innovation and growth. The backing from angel investor Leena Niemistö and family fund Thomasset Oy, along with private venture capital firms such as Nina Capital and Butterfly Ventures, has also played a pivotal role in driving our progress and success.

We are proud to now have a significant customer base in North America, with a growing presence across Europe and other global markets. Currently, we are designing over 28,000 insoles every month and meeting the diverse needs of our customers. As part of our commitment to ongoing customer support, our Senior Development team recently took an extended trip across the United States to visit customers, answer technical questions, and ensure all-round satisfaction with Taika3D software and bespoke implementations.

At Taika3D, we are excited about the future as we grow our customer base and broaden our product portfolio with innovative new offerings later this year, addressing critical needs and providing new devices.

We are forging strategic partnerships with cutting-edge 3D printing and scanning companies to provide unparalleled quality and service, as well as exploring new business models for the European market and participating in European Orthotic projects to strengthen and solidify our leadership in the industry. With the continued support of our investors and valued customers, we are well-positioned to help our network deliver outstanding services and products to their clients.

Trusted by leading manufacturers worldwide to generate thousands of pairs of insoles a day, we have been solving the challenge of creating complex custom designs in a fast and consistent way for central fabricators and large service providers in the orthotics industry since 2019.

As a pioneering software company endorsed by leading European academic institutions and key industry partners, we strive to harness the unlimited possibilities of design freedom and new innovation within the O&P industry.

Headquartered in Finland with a growing team in the UK and North America, our skilled engineering and business specialists solve a simple problem that delivers big results.

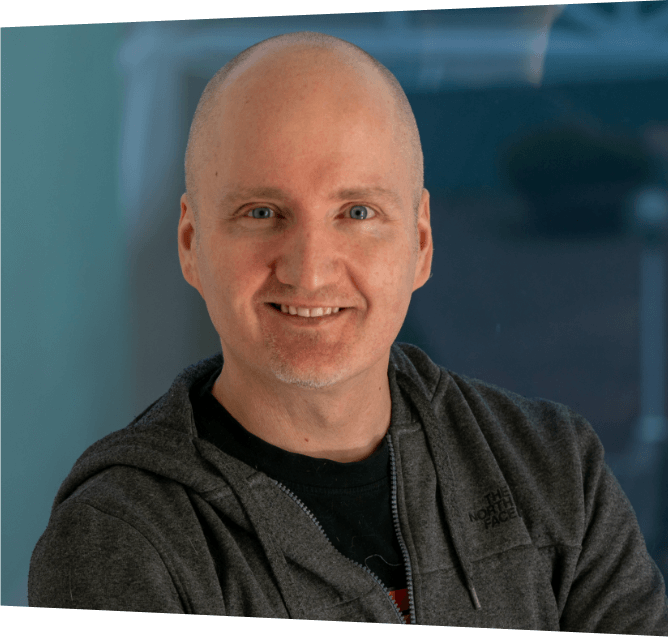

Steve has thirty years’ senior experience in the orthotics industry managing sales, leading clinical teams, running custom orthotic manufacturing operations, and delivering integrated services to the UK NHS and globally. He is passionate about innovating product and service to improve the lives of the users of rehabilitation products. He led the team that created the first commercially available 3d printed orthotics and saw first-hand the challenge of scaling the mass design of complex unique devices. Steve co-founded Taika3D Oy to meet the challenge of designing novel, individually fitted, orthotics and prosthetics efficiently – without compromise on fit, individuality, or effectiveness. He describes teaming up with the Finnish co-founders and building the team as incredibly rewarding and his favourite part of the role as meeting with all types of people within podiatry and O&P around the world talking about all aspects of design, automation and life.

Petja has years of experience as a development specialist in 3D solutions. Primarily focused on building and leading the talented development team at Taika3D, Petja remains an active developer and is responsible for many system implementations for our growing customer base. Prior to Taika3D Petja used to work for a company that manufactured EL-displays as a product developer. When not focusing on software, Petja enjoys spending time with his family and playing all sort of ball games such as Finnish nestball.

Rauno’s significant experience in production technologies and product development were fundamental in establishing Taika3D’s core team and defining our company vision – creating software for the design automation of custom orthotic devices. Rauno is proud of the team’s achievements to date, and of the system – which can handle such big data flows, and loves to see our software making a difference in the companies we serve. Already producing thousands of models every month for our customers, he is excited about the impact Taika3D’s design automation solution can have on the future of O&P design. In his free time, Rauno enjoys spending time with his kids and playing football, badminton and snowboarding.

Jari focuses his time on system architecture, design for manufacturing and managing our standard product platform, as well as being the key contact for many of our customers. With 20 years of experience in digital manufacturing of medical devices in roles such as R&D Director and Head of Technology in the O&P field, Jari has dedicated his career to the development of systems for the automation of 3D design, and the use of 3D printing for orthotic and prosthetic products. As visiting professor at Newcastle University, Jari champions innovation and engineering through a variety of engineering projects. At Taika3D, he is passionate about embracing design freedom for practitioners and new innovation to achieve better fit, comfort and compliance of medical devices, and ultimately better clinical outcomes with the potential for unlimited possibilities. In his free time Jari enjoys his two passions of motorcycle travel and martial arts!

As Co-Founder and Head of Technology, Timo plays a pivotal role in driving the company’s success and innovation. Timo is an accomplished colleague with a strong background in technology and entrepreneurship. He dedicates his time to developing and finely-tuning systems for 3D design automation, building bespoke solutions for every client and ensuring seamless integration with their existing pipelines. Timo is proud to be part of Taika3D’s revolutionary solution, delivering tangible value every day to customers in their production of custom made orthoses. Timo oversees the R&D function at Taika3D as well as being a key contact for some of our high-profile clients.

Teri’s appointment as Head of Marketing coincides with an exciting period of growth for the company, as we look to develop new markets while continuing to grow our solid customer base in the US and Europe. Teri has accumulated her marketing experience in the orthopaedic and aesthetic sectors, as well as time spent working overseas in trade and investment. Teri is excited to lead the marketing activity for Taika3D and to making a difference to our customers as they increasingly utilize design automation in their workflows to deliver better O&P products to users around the world. In her personal time, Teri enjoys taking part in open water swims, long dog walks and good food.

See our latest job openings or submit a general application today.

Discover how our range of software solutions can help transform your orthotics business.

Schedule a demonstration today.

Automated solutions for unique designs at scale

Improve reliability, accuracy and consistency of designs

Boost productivity – up to 60-100 pairs of custom insoles per designer per hour!

Produce complex user-specific models ready for 3D print or CNC machining

Full end-to-end digital solutions integrated into your business processes

Options for 3D scanning solutions and custom web order forms