As we settle into the new year, we’re leveraging the successes of the past months to drive continued growth at Taika3D and deliver even greater value for our customers. Here’s a snapshot of the progress and partnerships shaping our journey:

Welcoming New Customers

We’ve been working closely with new customers – some of the world’s leading manufacturers of orthotic and prosthetic devices – to seamlessly integrate our advanced design automation and scanning solutions into their workflows. This collaboration involves developing bespoke scanning applications, designing customized web order forms to capture patient information, and building APIs for smooth integration with existing software systems.

Our efforts also focus on understanding and optimizing customers’ order and user management processes. Recently, we reached a significant milestone by introducing new billing, compliance, and document management functionalities. Meanwhile, we continue tailoring our design automation module to meet each customer’s unique design requirements. This makes TaikaCreate a bespoke and efficient solution for automating custom insole design, complete with automatic scan cleaning, landmark recognition and placement. We collaborate with our customers to ensure the solution supports their preferred output method, whether through our milling manager or by generating 3D print files. Each implementation undergoes rigorous user acceptance and customer acceptance testing, guaranteeing that every element meets expectations before going live. This thorough process ensures a seamless transition to automated, efficient custom orthotic design.

Partnerships and Innovation

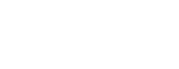

We’ve been collaborating closely with Structure and our valued customer KLM Labs to demonstrate how technology is transforming the O&P industry. During November’s National Diabetes Month, we showcased how advancements in 3D scanning and design automation enhance the precision and scalability of diabetic orthotics. By combining Structure’s 3D scanning platform with our automation tools, we’re empowering O&P professionals to deliver custom solutions more efficiently than ever.

Additionally, Dr. Doug Richie hosted an engaging webinar exploring how 3D scanning and design automation – powered by innovative solutions like Taika3D and Structure – are revolutionizing the creation of custom AFOs, such as the renowned Richie Brace. If you missed it, be sure to watch the webinar here to see how these technologies are reshaping workflows, enhancing precision, and improving patient care.

Spotlight on Our Team!

We recently celebrated Timo, our talented CTO, for his incredible contributions to Taika3D’s success. His expertise in electronics and unwavering dedication to advancing design automation have been instrumental in shaping our mission to revolutionize the O&P industry.

The Year Ahead!

As 2025 unfolds, we remain deeply grateful for our partners, customers, and team members who continue to make innovation possible every day. Thank you for being part of our journey to improve patient care through technology.

Wishing you continued success and happiness as 2025 gets fully underway!

Lastly, we’d be delighted to collaborate with our fantastic customers on case studies and other marketing initiatives. If you’re interested, please get in touch here.