Ready for your tour of the Taika3D system?

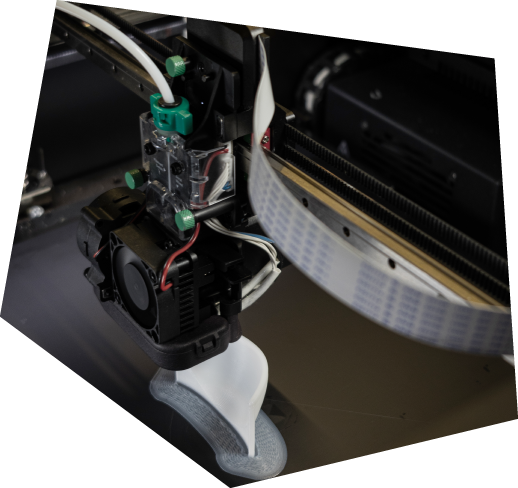

Array is a high-volume 3D printing system that uses robotics to enable the cost-effective production of custom insoles and orthoses.

The system pairs seamlessly with Taika3D’s software solution and can print up to 500 FO pairs of orthotic per month, per unit.

Together, Taika3D and Mosaic have created a powerful plug-n-play solution for producing custom orthotics on site, at scale.

Array takes the cost, mess, and waste out of custom foot orthotic production. Array directly prints functional and accommodative foot orthotics, producing over 500 pairs a month with limited operator intervention. The patented automation technology has revolutionized 3D printing production, making it truly accessible to O&P labs for the first time.

Array is compatible with a wide selection of O&P materials; Polypropylene & polycarbonate are popular choices for functional FOs, and Mosaic Aero offers a cushion-like feel – similar to an EVA foam – making it great for accommodative FOs.

– Aligned for FFF print beds

– Self generated supports

– Nested build volumes

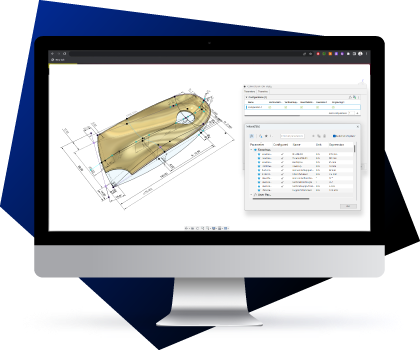

Discover how our range of software solutions can help transform your orthotics business.

Schedule a demonstration today.

Automated solutions for unique designs at scale

Improve reliability, accuracy and consistency of designs

Boost productivity – up to 60-100 pairs of custom insoles per designer per hour!

Produce complex user-specific models ready for 3D print or CNC machining

Full end-to-end digital solutions integrated into your business processes

Options for 3D scanning solutions and custom web order forms